Low-cost, single colour pad printers

The Jantech printers are rubber pad printing systems offering manual direct or offset small part marking (eg electronic components). These marking machines are a low-cost version of conventional padprinting equipment, which print single colour using rubber stamps and negligible amounts of paste letterpress inks in various colours.

Simple, reliable operation

The Jantech units operate by using an ink-roller, which spreads a thin layer of paste ink over a type-set (the typeset is made from metal, plastic or polymer). The print (which can be text or a logo) is then transferred directly onto the product - or onto a transfer pad for "offset" printing.

The paste type inks come in a variety of formulations and in a selection of colours

Versatile printing on many shapes

With the versatile Model 105 systems, you can imprint identification, numbering and coding on parts with flat, curved or irregular surfaces.

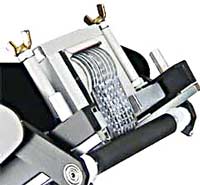

The Model 105 can accommodate a variety of Print Units, Rubber Stamp Printing Dies, Rubber Type, Photoengravings, Metal Type, and others. The Print Units are quickly changeable to convert to either direct or offset marking.

The Model 105 meets the demands of continuous production line use. The low maintenance design incorporates ball bearings at all important wear points. The exterior is color anodized to provide an attractive,durable finish

Direct VS Offset printing methods

| DIRECT | OFFSET |

|

|

|

| In this method, the print is transferred directly onto the product. Only flat areas are able to be printed this way. | With offset printing, the print is transferred onto a durable rubber pad first. The product is then pressed or rolled over the print - thus transferring the ink. Both flat and round parts can be marked on this method. |

Various accessories and print-units available

| Basic Print unit | |

|

|

The basic print unit can be used with:

You can make up your own alpha-numberic number with an alphabet/number set, or simply print the company's logo. |

| Band Numberer unit | |

|

For faster marking of single-line alpha-numberic codes such as dates, part numbers etc. Can be used for both offset and direct printing. |

| Serial Numbering unit | |

|

The serial numbering head is used to mark incrementing numbers with a click of a lever. This print unit is used only with the offset printing pads. |

| Precision Placement Fixture | |

|

The precision placement fixture is used for`hard to reach' surfaces such as depressions or close to obstructions. Simply print onto a small section of offset pad (cut to fit or clear the obstruction) and pull the lever to print the product. |

| Offset Hand-Stamp | |

|

|

Use this solution when you need to make a high quality mark an object that is too large or awkward for the capacity of the marking machine. The setup is for a removable block with a suitable size piece of offset printing pad on it. The machine work table is equipped with a positioning jig that enables accurate repeatable indexing of the offset hand stamp. The offset hand stamp is placed into the positioning jig and prepared for printing the same as you would for conventional offset marking work. The offset hand stamp is removed from the machine to make the mark, then returned to the machine for preparation for the next mark..

|

More accessories are available but not shown. Please contact us with details on your application so we can discuss an easy solution.

Demonstration Video:

Our demonstration video is now available: